Made in Germany -

made by Layher

Headquarters in Eibensbach

Our headquarters in Eibensbach offers a total of 250,000 m2 of space, including 110,000 m2 covered production and storage.

The proximity to development, logistics and administrative functions generates synergies that benefit our customers across the globe: seamless information exchange, rapid decision-making, exceptional manufacturing quality and effective production control.

Not least, production volume can be scaled in response to changing market needs and new customer requirements.

Factory 2 – Güglingen

Our second manufacturing plant is just a stone’s throw from the original location in Eibensbach.

The Gueglingen facility has a total area of 68,000 m2, with 38,000 m2 of covered production and storage space.

All our aluminium and wooden components are manufactured here.

Factory 3 – Cleebronn

Your future is what you make of it – which is why we established a third plant in 2023.

On a total area of 110,000 m2, it has a covered production and storage area of 80,000 m2 – partially in 2 storeys.

It includes our third galvanizing facility (with annual capacity of 120,000 t), a new, state-of-the-art steel manufacturing facility for our Allround product range, and an integrated logistics centre.

Layher takes responsibility

Layher, the world’s leading producer of scaffolding systems, is a family-owned company with its roots and its future – firmly in Gueglingen-Eibensbach.

Layher has its roots in a small town in south-west Germany. We are able to deliver made-in-Germany quality by remaining true to our origins – and by keeping development, production, sales, distribution and management in one place, where they have always been: in Gueglingen-Eibensbach.

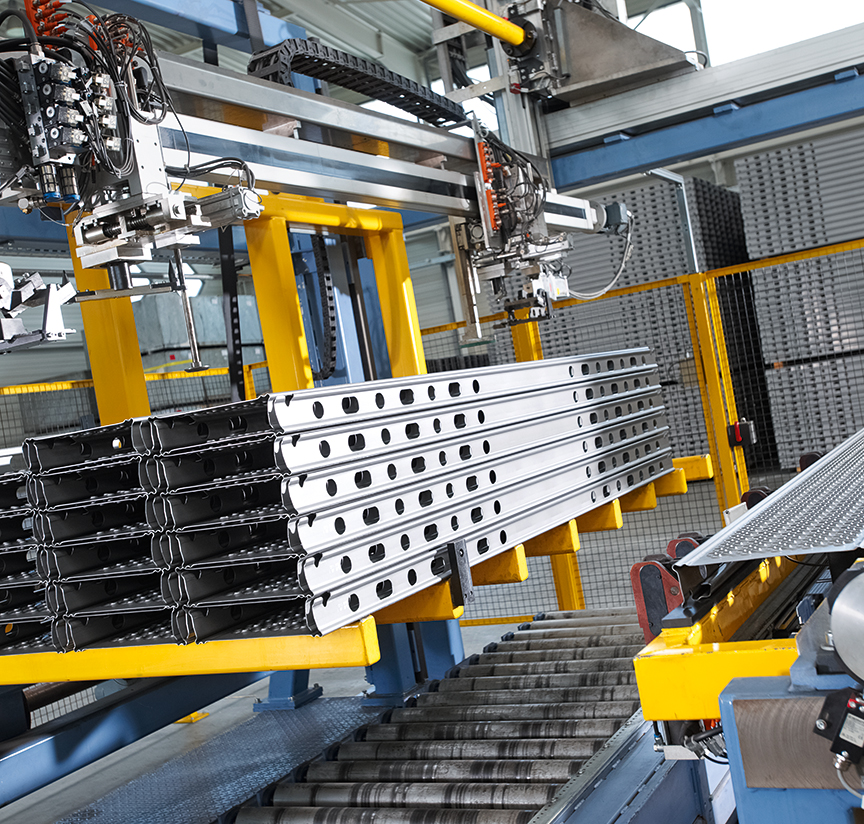

Maximum manufacturing precision

Layher continues to invest in the expansion of highly-automated manufacturing. This means that we can produce competitively in Germany and ensure the consistent high quality of our products.

Moderne Feuerverzinkerei

Modern inhouse hot-dip galvanising facility

The three fully automated and very modern galvanising facilities have a capacity of 290,000 t/year.

They are certified for compliance with DASt Directive 022 and meet the latest environmental regulations and requirements.

We process approximately 30,000 kilometers of steel tubing each and every year

We assume responsibility for the safety of our customers with every metre of tubing we make. This is why one of Layher’s core tasks is quality management. Our products are compliant with the very latest safety standards and possess DIN/ISO certification, German TÜV approval plus a range of other German and international seals for excellent quality. We have been DIN EN ISO 9001-certified since 1994.

Uncompromising quality

Although our suppliers are also certified, our own uncompromising commitment to quality is always implemented, from our intensive incoming goods inspection in-house to every production area.

We intentionally keep full control of our own core processes. We also believe in people power – so we rely on employees who have years of experience behind them, and we continually invest in skills development programmes.

This means that you can be sure you're working with the original

Quality management is not just about rigorous checks at each stage of production: correct marking and comprehensive documentation of all components is also important. So when its manufacture has been completed, every Layher component is stamped with information on the machine used for its manufacture, the date of manufacture and its various production parameters.